G32 screw thread cutting on a CNC Lathe

The G32 thread cycle allows us to have full control over each point of the positioning, although we tend to call it a cycle, it is actually modal in that it locks the rotation of the spindle to the feed rate, much like a manual lathe does. This gives us the ability to screw cut while programming point to point.

The above video lesson is covered in more depth during the CNC Lathe programming course available here

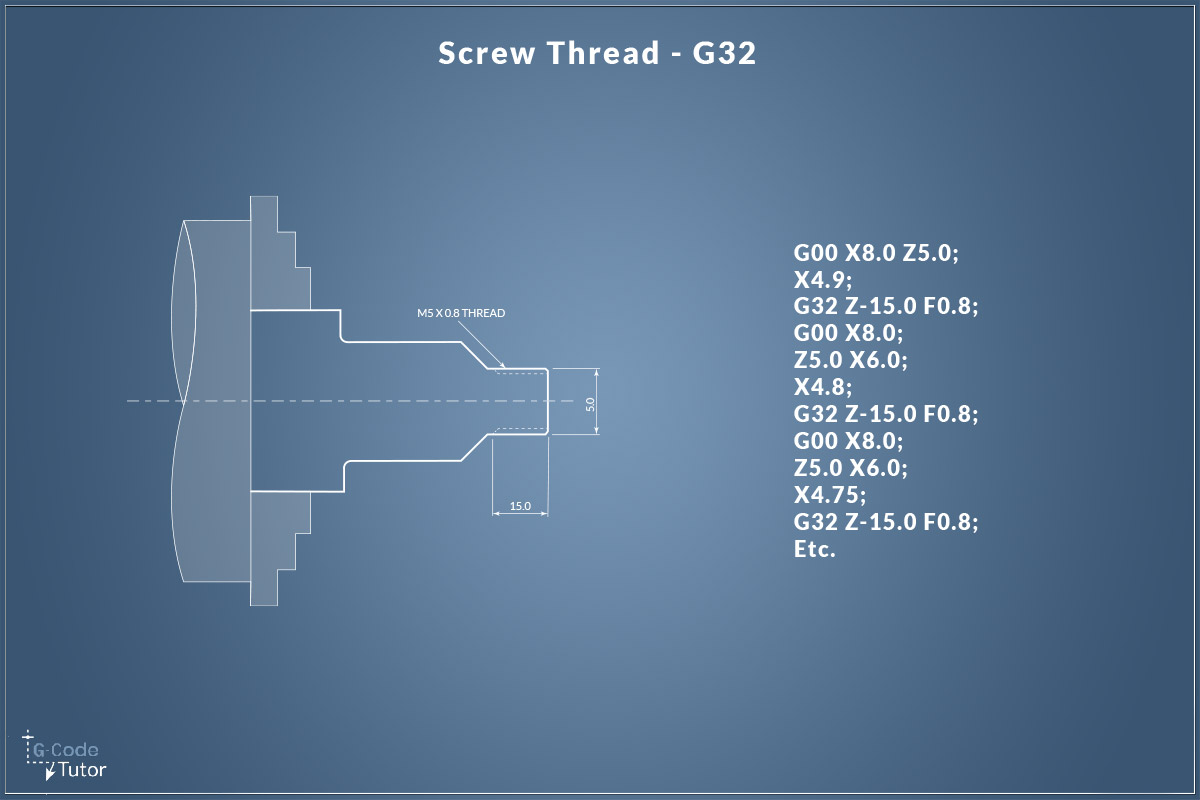

G32 Screw cutting mode

G00 X8.0 Z5.0;

X4.9;

G32 Z-15.0 F0.8;

G00 X8.0;

Z5.0 X6.0;

X4.8;

G32 Z-15.0 F0.8;

G00 X8.0;

Z5.0 X6.0;

X4.75;

G32 Z-15.0 F0.8;

Etc.

Before we look at cutting tapered threads, let's take a look at how the G32 works with a standard threading sequence. Here is a section of the program that is using the G32 G-Code.

Feel free to download the infographics on this page as a reference.

Let's look at each block to see what is happening.

G00 X8.0 Z5.0;

Rapid to a safe start position, assuming the datum is at the front face of the part.

X4.9;

Still in rapid mode with G00 active, we go down to the depth of the first cut, taking 0.1mm deep.

G32 Z-15.0 F0.8;

Here, we tell the machine to lock the spindle rotations to the feed rate so we can cut our screw thread in the same place each time. From now on, every time we call G32 the machine will cut a thread following the same path as the previous one.

The Z distance is the end of the thread and F is the pitch. We are cutting an M5 thread so the pitch is 0.8mm.

G00 X8.0;

After our first pass, we program the retract points. Coming up to X8.0mm gives us some clearance for when we move back to the start of the thread.

Z5.0 X6.0;

We can move in more than one axis to speed things up if we wish. Moving to 5mm to the right of the front face will give us a lead into the thread, to eliminate any backlash that may be present.

4.8;

Now we are ready to take the next cut, I've come down to take another 0.1mm deep pass. We can control the depth of each pass and decrease it as we get nearer the final depth.

G32 Z-15.0 F0.8;

G32 will lock our turret and spindle in the same place as before, so our next thread pass cuts over the top of the last. Then we just repeat this as we come down in X until our final depth of the thread.

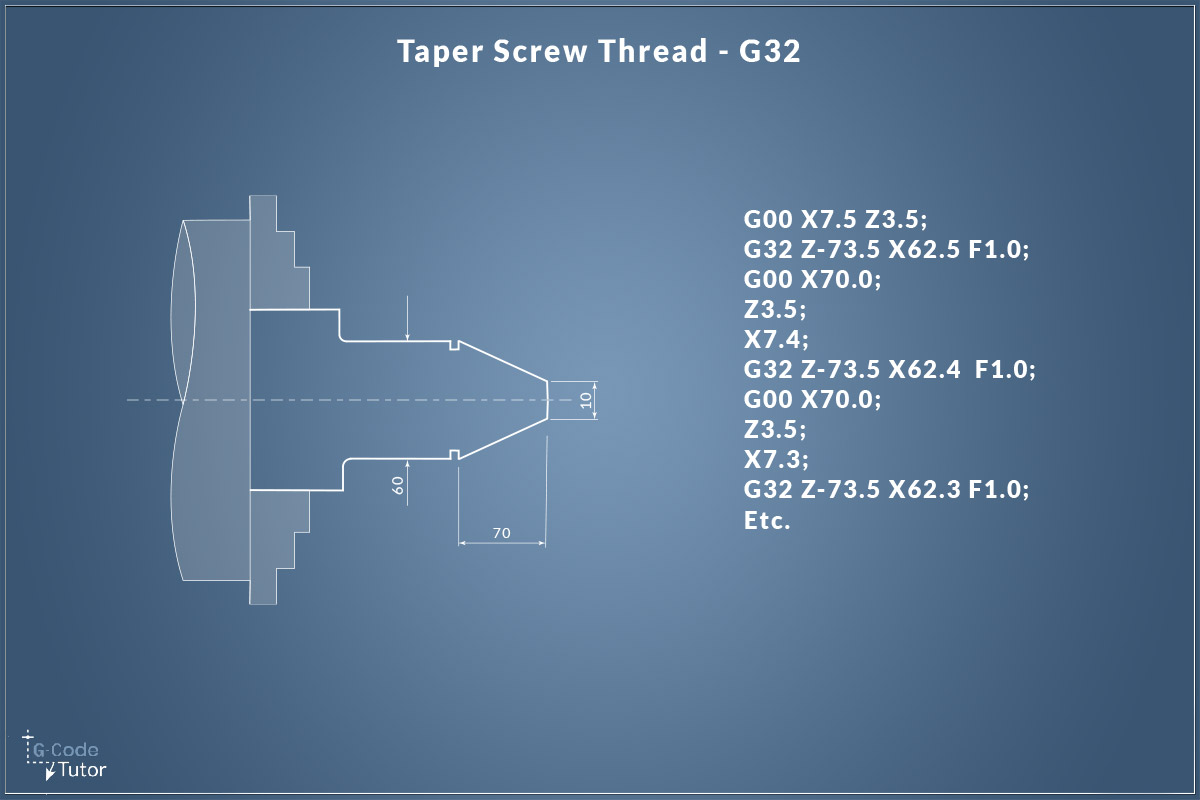

G32 Taper Thread

G00 X7.5 Z3.5;

G32 Z-73.5 X62.5 F1.0;

G00 X70.0;

Z3.5;

X7.4;

G32 Z-73.5 X62.4 F1.0;

G00 X70.0;

Z3.5;

X7.3;

G32 Z-73.5 X62.3 F1.0;

Etc.

To use G32 to produce a thread on a taper, its a similar process. The differences are we have to calculate the start and end positions and give an X dimension during the G32 block.

G00 X7.5 Z3.5;

When we calculate our start position, we have to take into account the angle of the taper. This is where our Trigonometry classes come into use. If you need to brush up on your trig, I have a course here.

G32 Z-73.5 X62.5 F1.0;

When we get to the G32 block, it is exactly the same but we also give an X dimension for the end position of our thread. I have gone past the endpoint by 3.5mm and calculated the X position to maintain the correct angle of the taper to give a run out cutting fresh air

Share this article

For a complete tutorial on CNC Lathe Programming check out my course.

The quickest way to learn CNC Programming