Which CNC Programming Style Best Suits Your Need?

The above video features GCodeTutor talking about this subject with Practical Machinist

One of the greatest USPs of CNC machines is that they introduce automation to your operations. However, the operators need to design the program to facilitate the autonomous functioning of the machines without compromising on accuracy, precision, and product quality. This fact remains regardless of whether you are running mini milling machines or scaling through the high-end models. CNC machine programmers have the opportunity to choose from three major CNC programming styles. Each enjoys a niche application, along with associated benefits and drawbacks. As a result, our choice of CNC programming style may vary from project to project. So, to empower the readers on making an informed and correct choice on the CNC programming styles, here is a detailed overview of the different types:

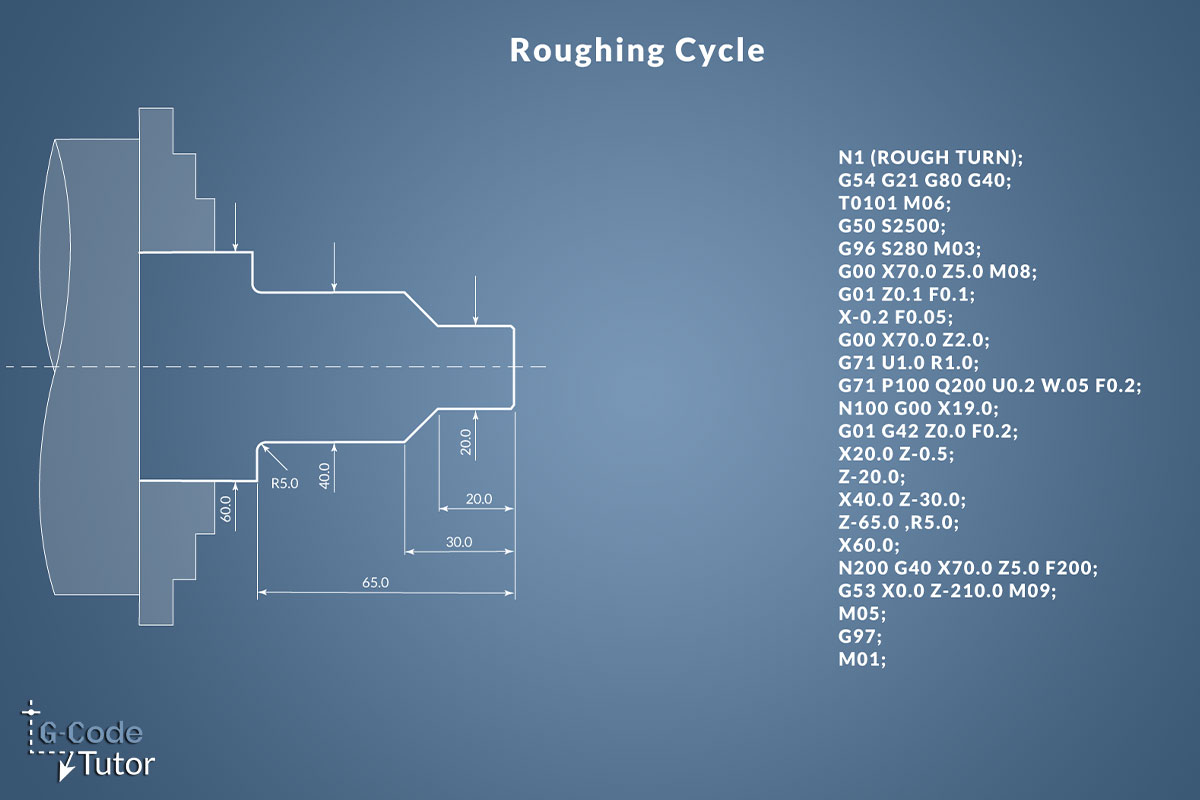

Manual G-Code Programming

As the name indicates, manual programming requires performing calculations and verifications minus the use of computers. It is one of the “old school” programming styles that meld together part human effort and part machine-led computation.

Here, the programmer must fashion the program in the same language as that employed by the CNC machine. Resultantly, they need to visualize the machining actions and operations and translate them into code and algorithms to deliver the desired results.

Even though machines are getting smarter and more capable, they are yet to develop intuitiveness that is at par with human instincts, creativity, and reasoning. As a result, manual programming offers the best results by optimizing machine performance, devising accurate tool paths, and mapping the program parametrically. It also maintains that the programmer follows the highest practices of quality and fidelity, which is a gold standard set by manual programming.

Despite its various advantages, manual programming must be used sparingly and judiciously. So set aside manual programming for extremely high-volume work where quality and machine optimization is the highest priority.

Advantages

Disadvantages

Conversational Programming

Programming CNC mills is made easier through conversational programming as it masks complexities without trading off the functionalities. As a result, it is perfect for entry-level machine operators and programmers.

Conversational programming allows the operator to generate snippets of the code at the machine in just a matter of a few minutes. And to facilitate this action, they make use of a library of data prompts for material, workpieces, geometry, tooling, etc., present in a programming wizard.

Once they have input these factors, the machine executes the remainder of the action for building the program. Of course, the CNC machine will verify and validate the workpiece design, toolpath, and other specifics before starting production.

Advantages

Disadvantages

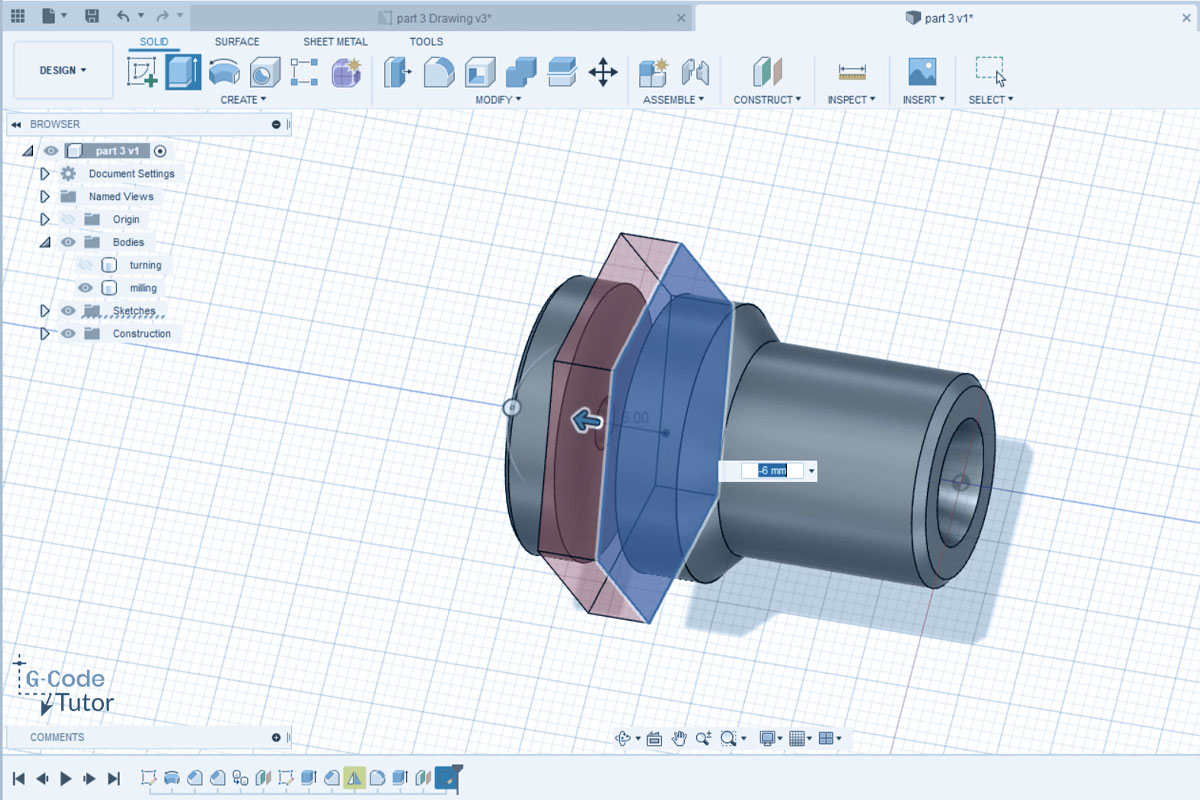

CAM System Programming

As Computer Aided Machines, or CAM, become more affordable, workshops can invest in them even while operating small pr mini CNC mill machines. And the decision to switch to it makes perfect sense as it can automatically produce the G-code language that controls CNC machines. As a result, single operators can program a gamut of CNC machines regardless of their programming requirements.

However, in all cases, the operator is responsible for the initial setup where the machine will require inputs on the workpiece geometry, part number, part name, machining operation, tool, etc. The CAD-CAM integration addresses some of the complexities involved in defining these specifications, especially with respect to the workpiece geometry.

Advantages

Disadvantages

Concluding Thoughts

To summarize everything explored so far, manual programming is best for high-volume productions where accuracy is of the essence, conversational programming is suitable for entry-level machine operators, and CAM programming serves well when you have a variety of CNC machines.

While these are the primary advantages linked with each programming style, they also experience certain limitations and drawbacks. So be sure to put these factors into perspective while deciding on the CNC programming style for the project.

Peter is actively involved in manufacturing processes and regularly contributes his insights for various blogs in CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in general.

Share this article

For a complete tutorial on CNC Lathe Programming check out my course.

The quickest way to learn CNC Programming