The above video lesson is part of my G-Code tutorials that I recorded with Practical Machinist. More can be found here

When we program with canned cycles, we greatly speed up the programming process and make the code easier for humans to read and edit.

CNC machines have two types of cycles available to us, along with canned cycles we also have multiple repetitive cycles. Before I discuss using canned cycles we need to understand what makes them different to multiple repetitive cycles.

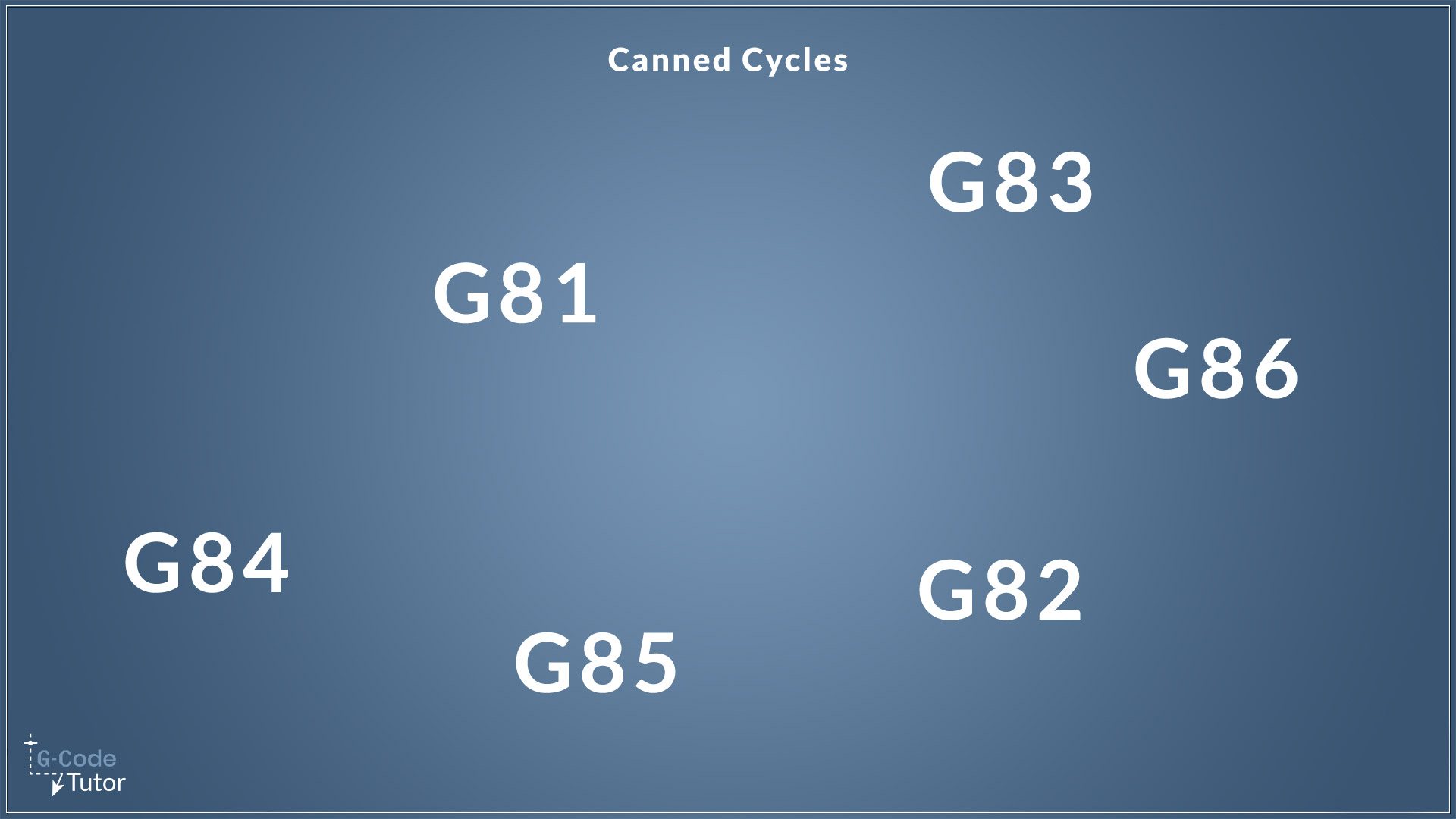

Canned Cycle Examples

The easiest way to identify a canned cycle is that we have to tell the machine to cancel it once we have finished with the cycle with G80.

The following cycles are classed as canned cycles:

Often when we look at G-Code produced by CAD/CAM software it will write the code longhand and not use cycles. When we program G-Code ourselves we use cycles to speed up the programming process and it makes our code much easier to read and write.

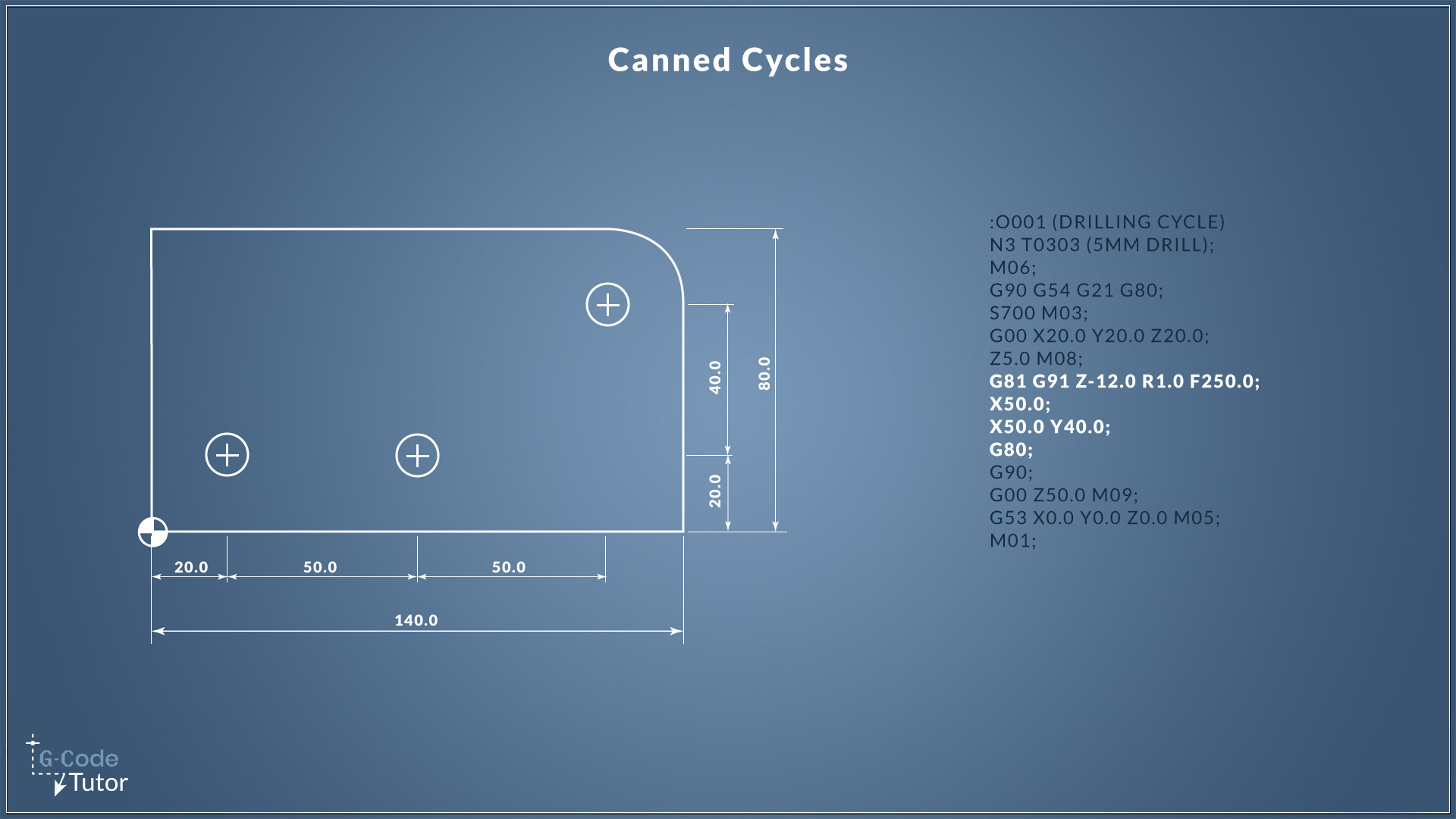

Using Canned Cycles

Lets take a look at a typical G81 canned drilling cycle

G81 Z-12.0 F250.0;

X50.0;

X50.0 Y40.0;

G80;

G81 Z-12.0 F250.0; - The G81 G-Code tells the machine that we wish to use a standard drilling cycle. Z-12.0 is the final depth of the drilled hole and F250.0 is our feed rate.

The X and Y positions that follow the G81 line are the locations of the holes we wish to drill.

To finish the cycle, we add G80 to cancel the active canned cycle to tell the machine that all the code that follows is not part of the drilling cycle.

The free lesson covers programming the G81 drilling cycle in more depth and is available here

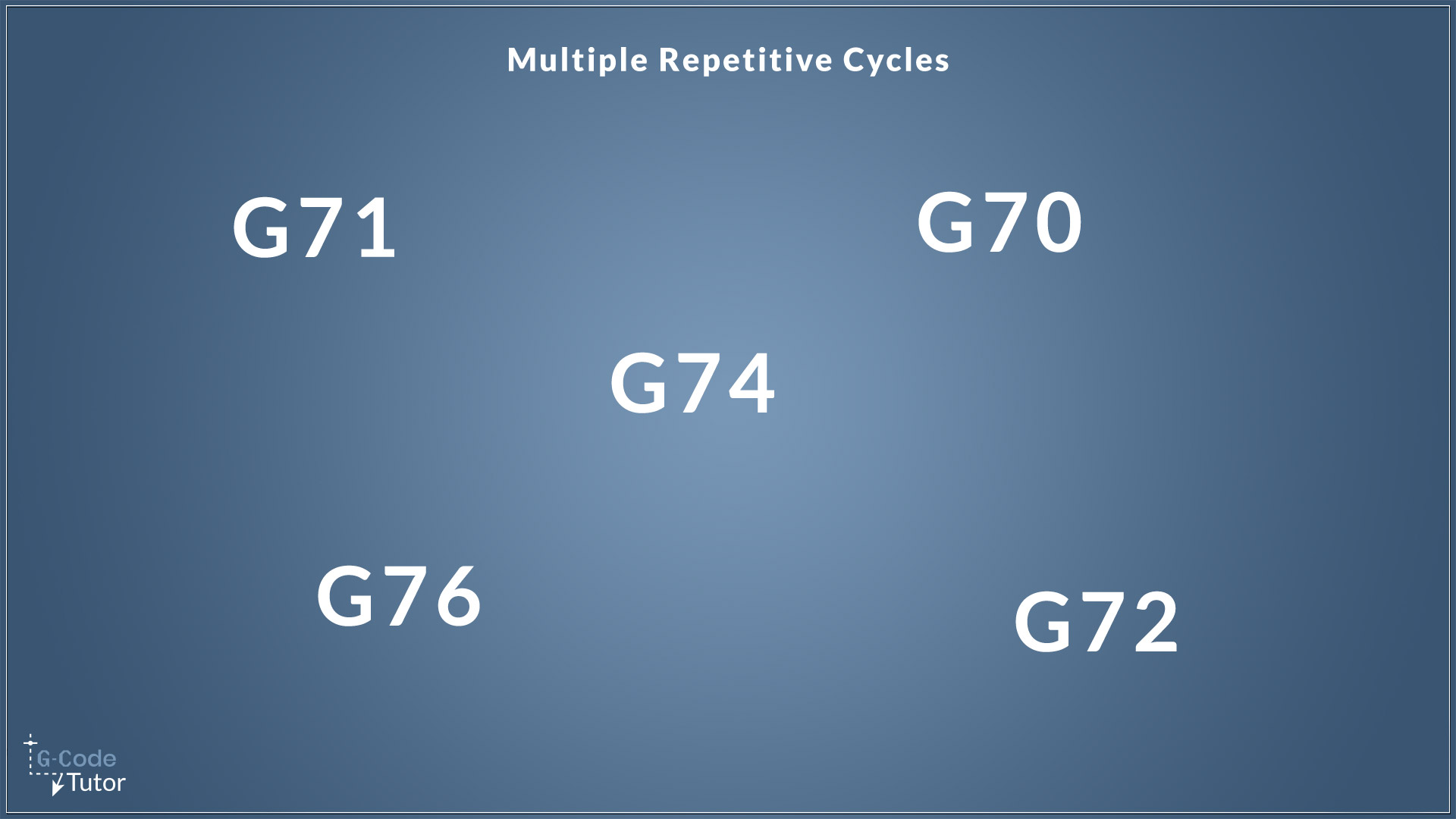

Multiple repetitive cycles

Mostly used on Lathes, the multiple repetitive cycle enables us to remove a lot of material with very few lines of code, it repeats tool paths to remove material until a profile that is often written in a subroutine is achieved.

The following is examples of Multiple repetitive cycles.

To learn more about each one, visit the linked page.

Multiple repetitive cycles do not need to be cancelled with G80

Share this article

To learn the basics of G Code programming, check out my Foundation course

The quickest way to learn CNC Programming