5 Best G-Code Simulators for Machining and 3D Printing

An impressive G-Code simulator can demarcate between a thriving process and an expensive failure. Programs that interact with the physical world to control robotics, 3D Printers, and CNC Machines perform one of the most vital tasks of programming, i.e., Debugging. Any loophole in the programming of these imperative physical machines can cost expensive and hazardous damage to the human workers, machines, or even the environment.

What Is a G-Code Simulator?

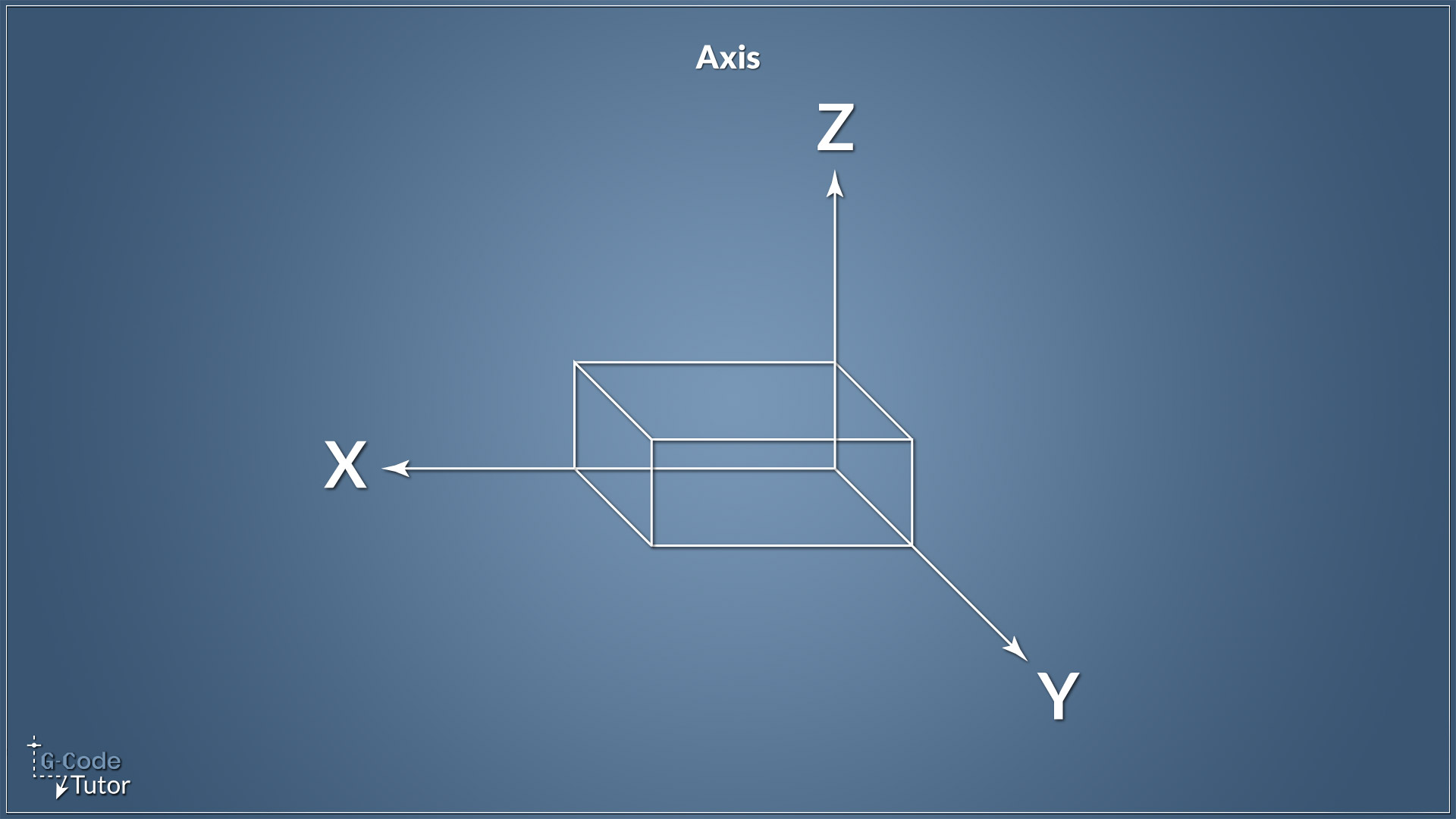

A G-Code simulator is a software tool through which the tool path of a CNC machine, which is made by following the instructions in a G-Code file, can be virtually represented. G-Code simulators can be simple simulators with a single image of the tool path, or they can also be complex tools that can detect collisions and plot the path in 3D.

Some important G-Codes that are used with 3D printers are:

Phase 1: Initialization

Phase 2: Printing

Phase 3: Reset the Printer

For more about programming 3D printers with G-Code: 3D printer programming with G-Code

This G-code simulation for online visualization is a great tool for testing skills. They give a solution to see how the machine tool will move and provide a quick and easy way to simulate G-Codes for machines and 3D Printers.

How to Choose the Best G-Code Simulator Software?

There are many ways to simulate G-Code, and it requires the best software to process it. For newbies and hobbyists, open-source or stand-alone G-Code simulators can check programs for CNC machines and 3D printers.

Whereas G-Code simulators from Python libraries or CNC turning centres would be worth checking out for researchers and professional programmers. These also work well for experts working in the industry who want to use convenient software that is user-friendly and robust. https://www.tsinfa.com/CNC-Turning-Center/

The 5 Best G-Code Simulators for Machining and 3D Printing

Stand-Alone G-Code Simulator

This is a simple yet effective software tool that shows the path by professionally simulating G-Code files. Although it does not interface with CNC machines or 3D printers, it helps draw relevant shapes that it is supposed to. For example, an NC Viewer is a handy online tool for quick visualization.

Slicer Software (For 3D Printing)

A Slicer is a software tool that converts your CAD model into G-Code. While a G-code simulator may sound enticing, but there are chances that we may already be using it in programs while operating 3D models using the slicer software. This 3D slicer software makes a 3D model 3D printable, slicing it into horizontal layers according to the set layer thickness and generating a road map for the nozzle. Hence, the printer understands the instructions well

The slicer software also operates the print settings of a 3D printer. The slicers use the layer viewing mode, the G-Code simulator, which generates a 3D simulation and shows how each layer is built, layer by layer. This mode helps to identify when the model may fail when 3D printing starts. Different colours are used to indicate various types of lines and structures to analyze each step of the 3D printing process and see what it looks like.

Almost every slicer program offers a G-code preview. However, experts in the industry may require serious 3D printing software to understand simulations. These tools help identify all relevant parameters like temperature, structural stresses, and the part’s performance under load.

RoboDK Simulators for Machining and 3D Printing

This works as a robot for machining, like CNC Turning or 3D printing, and effectively works with G-Code files that can easily be loaded into the software. This can easily simulate the path, after which the program can be sent to the robot’s controller without having to do much robot programming. Here are some benefits:

Libraries Like Python or MATLAB

For experts and researchers, libraries are helpful to use a G-Code for the preferred programming language. This is the advanced analysis on G-Code or link with CNC programming and can be used as part of a research project or while developing a 3D printer. Some common examples are G-Code Reader as an extension for MATLAB, PyCNC as a library for Python, and GSIM as an open-source 2D simulator written in Python.

These applications can help you automate the entire path – from research to production and complete tasks more easily than with custom programming. MATLAB and Python can help the professional programmer delve deeper into the simulation and meet the desired objective.

CAM Package

Computer-Aided Manufacturing (CAM) programs are how the G-Code files are generated in the first place. The renowned programs include Fusion 360, Inventor, or MasterCam. These can simulate G-Codes and link the software directly with CNC machines or 3D printers. Some of its more important features are:

Conclusion

The Objective of G-Code Simulators is to show a way how the machine tool will move. As discussed, there are quite a few options available for simulating G-Codes. Whether working as a hobbyist, a professional programmer, or in the industry, G-Code Simulators are easy-to-use and robust software that will save you from unnecessary headaches.

Also, check out our very own CNC simulator from NCViewer.

Vincent Hua is the Marketing Manager at TSINFA. He is passionate about helping people understand high-end and complex manufacturing processes. Besides writing and contributing his insights, Vincent is very keen on technological innovation that helps build highly precise and stable CNC Machinery.

Share this article

For a complete tutorial on 3D printer Programming with G-Code, check out my course.

The quickest way to learn G-Code